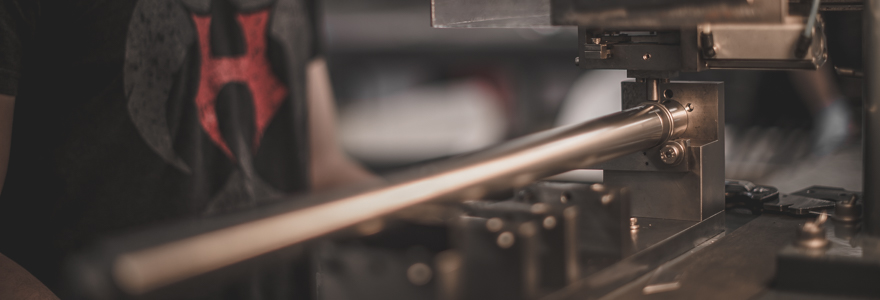

The manufacturing process at BA begins with truckloads of the highest quality 416R & CrMoV steel delivered directly to us. In preparation for the button rifled process, barstock is cut to length then drilled, reamed, and rifled. Using custom designed blanking tools, every production barrel from BA carries match-grade tolerancing with bore uniformity of .0003” or better. It’s normal to see barrels coming off the line at less than .00015” variation through the entire blank.

Once delivered to Turning, we strive to honor the full potential of the blank through the entire manufacturing process. Every element of our turning production is designed around our original goal of combining critical elements of custom barrel making with the value benefits of high-volume CNC production.

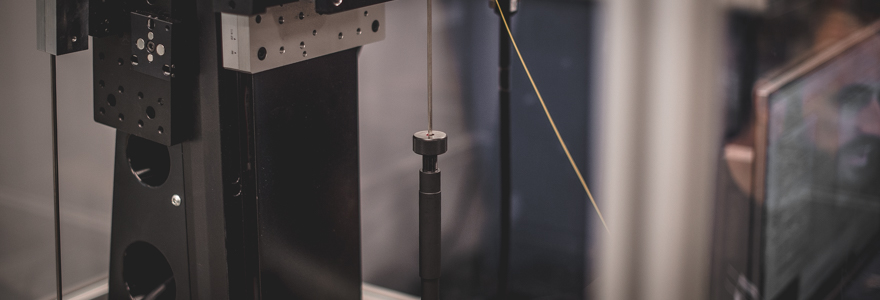

BA controls and assures quality through contact gauging, air gauging, and laser light measurement. In addition to our fully staffed QC department, we have built in redundancy through our Production Support Specialists who perform in-process inspection and report to the Production Manager, ensuring both departments are fully informed and able to react as needed.

After Quality Control, barrels are sent to outside services for any coating treatments. Once returned, our Fulfillment department performs a whole new set of QC inspection points during the assembly and final testing process. Our specially designed manufacturing process and the commitment of our personnel to honoring the steel’s full potential are the reasons we’re able to deliver hundreds of thousands of barrels a year with the value and quality you’ve come to know and trust.